As with articulated vehicles, a rigid truck with a drawbar trailer requires the operator to physically connect a specific rear camera Suzie cable in order to see an image from the rear of the drawbar trailer. With SCC’s revolutionary X-Wire technology, there is no need for an additional camera Suzie on the rigid/drawbar trailer. As soon as the standard Suzies are connected, the X-Wire unit connects automatically with the appropriate monitor and DVR in the rigid vehicle. This can be used in conjunction with a rear camera and X-Wire unit on the rigid vehicle that automatically disconnects once the drawbar trailer is connected providing the correct rear image with no driver input required.

If you’d like to configure your own custom safety pack or speak to one of our specialists for some additional information on how our systems can eliminate driver error in your fleet, please:

Any dealership will be able to tell you about the problems that can accompany installing aftermarket products in house, be it the difficulty of the installation itself, or the risk of it coming back to us should anything go wrong. So much so, in fact, that we often prefer to send this kind of work out as it just isn’t worth the hassle, even though it means we lose out on a valuable extra source of income. Having spent some time working with SCC, they helped us realise this doesn’t have to be the case. Indeed, the work should be done in house, provided you have the right product, training and support, and SCC gives us all of these things. Their products are some of the easiest to install we have come across and the extra income is, of course, a huge bonus for us, but what’s more, the peace of mind knowing that SCC are on hand should anything go wrong on the road means we can sell to our customers with confidence.

We contracted SCC to install our fleet with equipment required to progress to FORS Silver Standard. This included front and rear blind spot sensor systems, audible left-turn alarm and a fresnel lens. The total cost installed was £785 per vehicle. Since having the systems fitted we have noticed a significant reduction in minor impact damage which has resulted in an annual cost saving across the fleet of £1832 per vehicle.

If anything goes wrong on one of our vehicles, not only is it a problem for our customers, but the pressure and stress mean it can be a huge headache for us. Even before we started trading with them, we were very impressed by the level of support offered by SCC as this is something we just don’t see in our industry. Most importantly, the support actually provided goes above and beyond what we had expected. No request has been too great and it is exactly this level of support that we need to help keep our profits up, workshops busy, and our customers happy. Our relationship with SCC isn’t just that of customer and supplier, it’s very much a partnership, with their ultimate goal being to do everything they can to help make us as much money as possible. Why wouldn’t you want to do business with them?

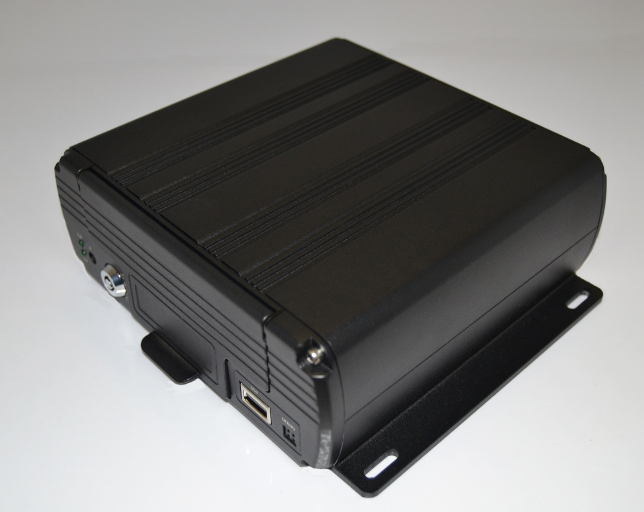

We have had SCC 4 camera recording systems installed on our vehicles along with front corner blind sport proximity sensor systems. This was done to be compliant in London and the surrounding areas. However, when we analysed the running costs of the vehicles installed with the safety equipment against the ones that don’t have the systems installed, we have shown a cost saving of 47% (£2,203) per truck on minor impact damage. This shows that having the systems fitted is actually saving the company money.

We have had SCC systems installed on our vehicles for just over 2 years. During this time, incidents (both minor and major) have noticeably decreased. The initial outlay for the equipment has been saved many times over and continues to do so. The reduction of insurance claims for major incidents has also reflected very favourably on our premiums.